Harmony Industry Diamond (H.I.D.)

Harmony Industry Diamond (H.I.D.)

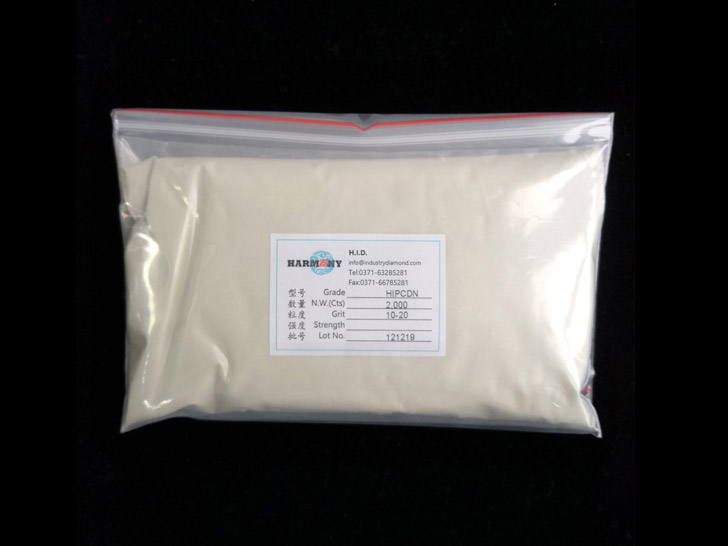

| Place of Origin: | Zhengzhou China (Mainland) |

| Brand Name: | Harmony |

| Production method: | High pressure high temperature |

| Size: | 0.05 - 60um |

| Color: | Yellow, green |

| MoQ: | 1000 carats |

| Application: | Precision grinding, polishing and lapping |

| Packaging: | Plastic bag/bottle, carton |

| HS Code: | 71051020.00 |

| OEM/ODM: | Size tailord |

Более правильная форма кристаллов благодаря запатентованному технологическому процессу, почти сферическая форма частиц, более концентрированное распределение частиц по размерам и низкое содержание примесей, очень чистая поверхность частиц, легко диспергируется в различные типы векторов и прочно сочетается с различными связующими.

Подходит для прецизионного шлифования оптического стекла, оптических шлифовальных пленок, оптических шлифовальных кругов, прецизионных полировальных пластин, прецизионных шлифовальных кругов из кремниевых материалов для обработки сапфиров, прецизионных обрабатывающих инструментов для обработки нефритовых драгоценных камней.

Необработанное сырье взято из высококачественного алмаза серии SCD, использует передовые технологии производства в сочетании с уникальной технологией формирования частиц, произведенной на основе стандартизации международных требований. Правильная форма кристаллов, низкое содержание примесей и распределение частиц по размерам соответствуют национальным стандартам.

Подходит для абразивных инструментов для склеивания металла и керамики, всех видов гальванических инструментов, шлифовальной пасты и суспензии.

Необработанное сырье взято из серии green RVD обычного алмаза с передовой международной технологией производства в соответствии со стандартами требований. Неправильная форма кристаллов, содержание примесей и распределение частиц по размерам соответствуют национальным стандартам.

Подходит для абразивных инструментов, скрепленных смолой, всех видов гальванических инструментов, шлифовальной пасты и суспензии.

Изготовлен из прочного алмаза mbd, обработанного специальной обработкой, с суперчистой поверхностью частиц, общее содержание всех видов металлических примесей контролируется на уровне ppm; хорошая и стабильная способность к диспергированию и суспендированию как на водной, так и на масляной основе для обеспечения эффективности шлифования и полировки; узкий psd, высокое содержание частиц очень плотной формы, хорошая термостойкость, высокая износостойкость.

Используется при изготовлении pdc и алмазных суспензий для притирки, шлифования, полировки многих видов поверхностей материалов, в том числе требующих специального кондиционирования.

Он изготовлен из высококачественного и высокопрочного алмаза в качестве сырья, на основе традиционной технологии алмазного порошка, путем проведения специальной обработки для придания формы кристаллам и очистки поверхности, частицы обладают характеристиками очень чистой поверхности, высокой ударной вязкости, постоянной формы кристаллов, хорошей термостойкости и износостойкости. Благодаря нашей уникальной технологии устранения критических размеров и контроля соотношения длины и ширины частицы также имеют строго концентрированный PSD и очень высокое содержание эффективно измельчаемой крупы. Кроме того, доступны различные изделия с покрытием, которое значительно улучшает сцепление между алмазными частицами и скреплением, тем самым продлевая срок службы инструмента и улучшая остроту. Это также способствует отводу тепла внутри системы скрепления, что увеличивает срок службы изделий.

If you need our products please write down any questions, we will reply as soon as possible.